Debranning

PeriTec is a unique process, developed by Satake, which can be utilised in the cereal milling industry for applications such as debranning wheat, dehulling barley and degerming maize.

The PeriTec process sequentially removes the outer kernel bran layers prior to milling or subsequent processing, which optimises the yield and reduces the amount of bran contamination in the finished product.

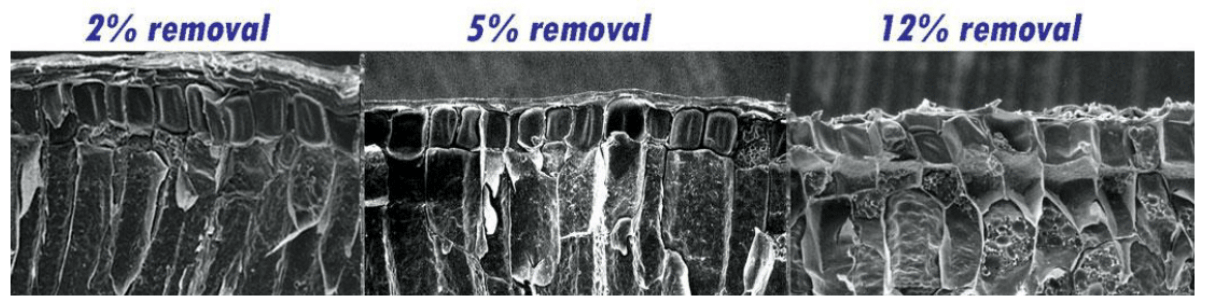

The equipment used in the PeriTec process is able to sequentially strip the bran layers, giving the degree of control that the commercial flour miller demands. Within one machine bran removal rates can be adjusted from a few percent in order to heavy scour the outside of the grain to 10 - 12 % required for some specialist processes. Satake's many years of experience shows that that for the majority of mills, the optimum bran removal for high quality bread making flour is in the region of 6 - 6.5% and for durum semolina milling 8 - 8.5%.

Another advantage of the PeriTec System is its flexibility. The ability to adjust the amount of bran removed is ideal for mills required to produce a range of products such as wholemeal, brown and white flours. When producing wholemeal flours, the abrasion chamber can be by-passed and only the friction chamber used to heavy scour. When the mill produces white flour, the whole machine is used and higher optimum debranning rates are achieved.

The process is fully automated and features a control system that adjusts for variations in the nature of the raw product being fed into the system.

The PeriTec Debranning Process also has important applications in starch and ethanol product systems, where the removal of bran prior to milling can substantially improvethe efficiency and performance of subsequent processes.